The Common Types of Stainless Steel for Optimal Applications

Stainless steel has become a cornerstone in various industries due to its exceptional corrosion resistance, durability, and aesthetic appeal. Understanding the common types of stainless steel is crucial for selecting the right material for optimal applications.

What is a Stainless Steel?

Before diving into the various types and grades, let's briefly understand what stainless steel is. Stainless steel is an alloy of iron, chromium, and other elements, with chromium playing a key role in imparting its corrosion-resistant properties. The addition of other elements like nickel and molybdenum further enhances its strength and versatility.

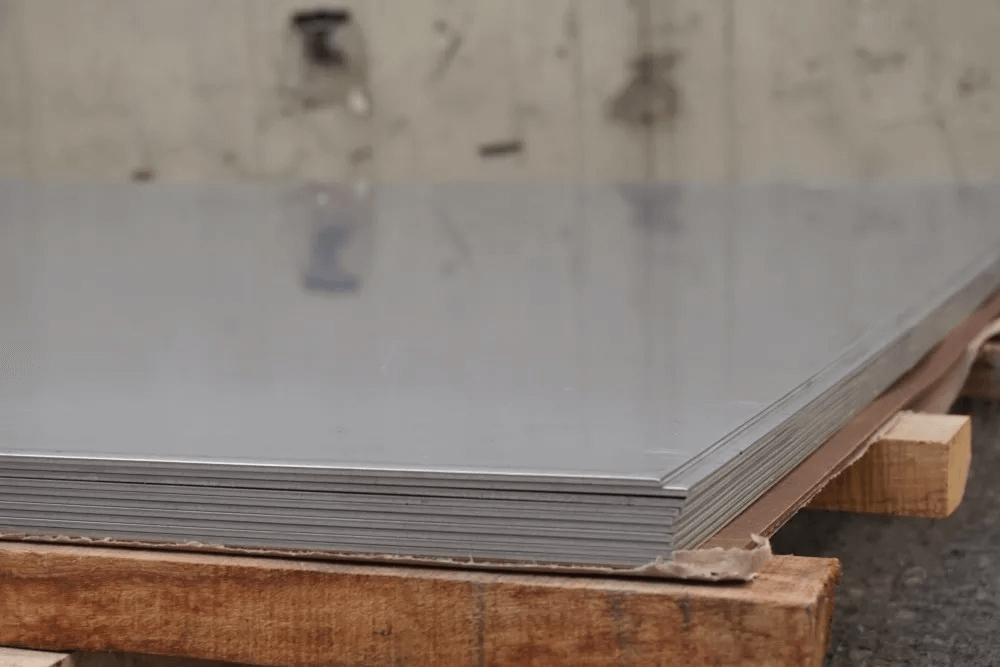

The Wide Range of Grades and Sizes:

Sheet/Plate Applications

Grade 304: The Universal Workhorse

Widely used in sheet/plate applications, Grade 304 finds its place in architectural design, kitchen equipment, and various industrial components. Known for its versatility and corrosion resistance, it is a go-to choice in many industries.

Grade 316: Resilience in Challenging Environments

With superior corrosion resistance, Grade 316 excels in marine environments, chemical processing, and medical equipment manufacturing. Its durability makes it a preferred material for sheet/plate applications in industries where exposure to harsh conditions is prevalent.

Grade 317: Conquering Acidic Challenges

Specifically designed for environments with high acidity, Grade 317 is a stalwart in chemical processing, pharmaceuticals, and pulp and paper industries. Its heightened corrosion resistance makes it suitable for sheet/plate applications in demanding settings.

Grade 2205: The Duplex Dynamo

A duplex stainless steel, Grade 2205 combines the best of both austenitic and ferritic stainless steels. It is widely used in sheet/plate applications, particularly in industries such as oil and gas, where its strength and corrosion resistance are indispensable.

Grade 904: High-Alloy Elegance

With a high alloy content, Grade 904 shines in aggressive acidic conditions. Its application in sheet/plate settings is prominent in industries like chemical processing, petrochemicals, and pharmaceuticals, where corrosion resistance is paramount.

Shaft/Round Bar Applications

Grade 304: The Time-Tested Choice

Grade 304’s corrosion resistance and excellent fabrication properties make it a reliable choice. It finds applications in manufacturing, automotive, and general machinery, where its strength and versatility shine.

Grade 316: Resilient Performance

Similar to sheet/plate applications, Grade 316’s superior corrosion resistance extends to round bars, making it ideal for use in demanding environments, such as marine and chemical processing industries.

Grade 2205: Strength and Duplex Brilliance

The duplex strength of Grade 2205 translates seamlessly to shaft applications, contributing robustness to machinery in various industries. Its corrosion resistance and durability make it a valuable choice in demanding operational conditions.

Grade 431: The Martensitic Warrior

Known for its high strength and hardness, Grade 431 is a martensitic stainless steel suitable for shafts in industries requiring exceptional wear resistance, such as bearings and gears in manufacturing.

In conclusion, understanding the common types of stainless steel and their applications is essential for making informed decisions in various industries. Whether in the form of versatile sheet/plate applications or robust shafts/round bars, these showcase the diverse capabilities of stainless steel. As industries continue to evolve, the reliability and adaptability of stainless steel grades remain indispensable in creating sustainable and enduring solutions.