CNC Laser Cutting: Precision Engineering Redefined

Understanding CNC Laser Cutting

Demystifying the Process

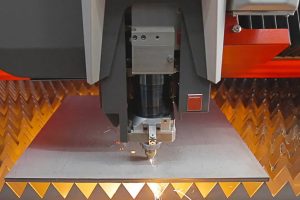

CNC laser cutting possesses technology that ensures exceptional accuracy, making it indispensable in industries that require high-precision fabrication, from intricate prototypes to complex patterns.

There are two types of lasers cutting technology available today:

|

CO₂ Laser Cutting

|

|---|

| An older technology that uses mirrors to direct the laser beam to the cutting torch. While still effective for various applications, CO₂ lasers are gradually being replaced due to higher maintenance requirements and lower energy efficiency.

|

|

Fiber Laser Cutting

|

|---|

| A newer, more advanced technology that transmits the laser beam through fiber optics. Fiber lasers are faster, more energy-efficient, and capable of cutting reflective materials like aluminium and copper with greater precision. Due to these advantages, fiber laser technology is rapidly replacing CO₂ lasers in industrial applications.

|

By leveraging both CO₂ and fiber laser cutting machines, manufacturers can ensure optimal cutting solutions for a wide range of materials and project requirements.

Materials Conquered by the Laser Cutter

CNC laser cutting showcases remarkable versatility by accommodating a wide array of materials. However, CO₂ and fiber laser technologies have different strengths when cutting certain materials, making each better suited for specific applications.

CNC laser cutting is extensively used in metal processing, ensuring high precision and efficiency. Metals can be categorized into:

Ferrous Metals

Mild Steel

Both CO₂ and fiber lasers can cut mild steel, but fiber lasers offer faster cutting speeds and better energy efficiency.

Stainless Steel

Fiber lasers are the preferred choice for cutting stainless steel due to their ability to handle reflective materials with minimal heat distortion.

Carbon Steel

Suitable for both CO₂ and fiber lasers, with fiber lasers delivering cleaner and faster cuts.

Non-Ferrous Metals

Best cut using fiber lasers, which prevent material warping and deliver high-speed, precise cuts.Brass

Fiber lasers perform significantly better than CO₂ lasers when cutting brass due to reduced reflectivity and increased efficiency.Copper

Fiber lasers are ideal as they handle reflective surfaces better and cut faster than CO₂ lasers.

Non-Metal Materials

Acrylics

CO₂ lasers are highly effective for cutting acrylics as they provide smooth, polished edges without additional finishing. Fiber lasers are less effective for acrylic cutting as they can cause melting or charring.

Rubber

CO₂ lasers are generally used for rubber cutting due to their ability to create clean, precise cuts without excessive material burning.

Amidst this realm of precision engineering, CNC laser cutting has become an essential tool for industries requiring high accuracy and efficiency. With state-of-the-art equipment and skilled operators, this technology ensures projects are executed with meticulous attention to detail. Whether metal fabrication, signage production, or artistic creations, CNC laser cutting delivers reliable and precise results.

In conclusion, CNC laser cutting is a technological marvel reshaping the manufacturing landscape. Its ability to handle intricate designs, optimize material usage, and enhance production speed makes it indispensable across various industries. As this technology continues to advance, its precision and versatility will undoubtedly play a pivotal role in shaping the future of manufacturing.