Metal sheets play a pivotal role in various industries, offering structural support, ventilation, and aesthetic appeal. Two common options are expanded mesh and perforated metal, each with distinct characteristics. In this article, we’ll explore the differences and help you understand which one might be the better fit for your needs.

Expanded Mesh vs. Perforated Metal: Weighing the Options

Before diving into applications, let’s briefly understand the differences between expanded mesh and perforated metal.

|

Expanded Mesh

|

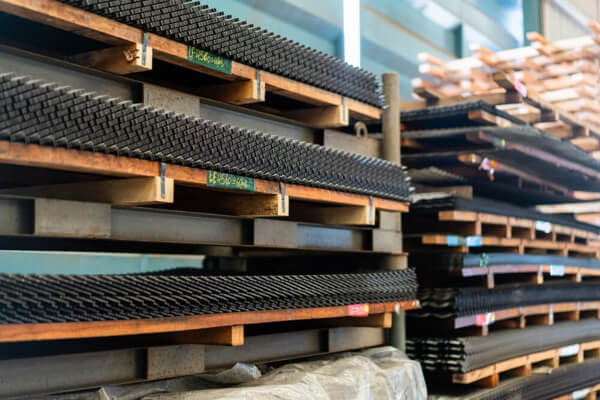

| Created by cutting and stretching metal sheets, expanded mesh features a diamond-shaped pattern. This process enhances its strength while keeping it lightweight.

|

|

Perforated Metal

|

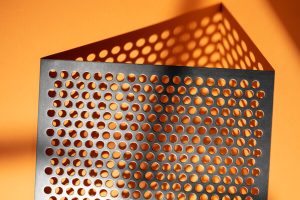

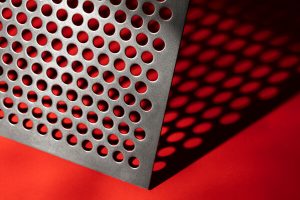

| Crafted by puncturing holes into metal sheets, perforated metal offers precise control over hole patterns and sizes.

|

Now, let’s delve into their applications.

Expanded Mesh Applications:

Architectural Marvels

The versatility of expanded mesh makes it a favorite in architectural projects. From facades to decorative elements, the diamond-shaped pattern allows for creativity while providing structural integrity.

Construction Projects

In construction, strength and flexibility are paramount. Expanded mesh finds its place in applications like walkways, fencing, and platform gratings due to its ability to offer robust support without adding excessive weight.

Industrial Platforms

Industrial settings often require materials that can withstand heavy loads while allowing air and light to pass through. Expanded mesh, with its open design, is ideal for platforms, catwalks, and flooring in such environments.

Security Fencing

The durability of expanded mesh makes it an excellent choice for security fencing. The interlocked strands create a sturdy barrier while allowing visibility.

Perforated Metal Applications:

HVAC Systems

Perforated metal’s precise hole patterns find application in HVAC systems, where controlled airflow is essential. These sheets help in creating efficient and optimized ventilation systems.

Acoustic Panels

The controlled openness of perforated metal makes it valuable in crafting acoustic panels. The holes contribute to sound absorption and dispersion, making it suitable for auditoriums, recording studios, and theaters.

Decorative Elements

Perforated metal is often employed in creating decorative elements for both interior and exterior spaces. The ability to customize hole patterns allows for intricate and aesthetically pleasing designs.

Filtration and Screening

Industries requiring filtration and screening solutions benefit from perforated metal sheets. These can be used in water filtration, sieving, and separation processes.

Choosing the Right Fit

The decision between expanded mesh and perforated metal depends on the specific requirements of your project. If structural integrity and versatility are crucial, expanded mesh is an excellent choice. On the other hand, if precise hole patterns and controlled open areas are essential, perforated metal becomes the preferred option.

In the realm of metal sheets, the choice between expanded mesh and perforated metal boils down to your project’s needs. Leon Fuat, with its expertise in both, ensures that you have access to high-quality materials tailored to your specifications. Whether you’re constructing an architectural masterpiece, an industrial platform, or implementing HVAC solutions, understanding the applications of these materials will guide you in making the right choice for a successful project.